The last week of December saw our Mozambique equipment rental and material handling team participate in the assembly of the SMP rig at the P-25 site in Pande. For this successful operation we used our 80T Grove rough terrain crane under the highest health, safety, environment and quality standards. Many thanks to our client for continuously trusting in our services and our Mozambique team for the excellent execution of the work required.

Load of The Month: 52 Truckloads of Steel Pipes

In December we transported 52 truckloads of steel pipes from Dar es Salaam port to Kitwe, Zambia.

This operation presented several interesting challenges. As per our in-house standards, we ensure that each truck is serviced after every trip. Due to the quantities required for this project and the schedule, our workshop team was required to work efficiently in order to turn around all the required trucks within 72 hrs of arrival in Dar.

As the pipes were of different sizes and weight, they had to be loaded onto the trucks and secured with special lashing equipment under the guidance of professional loading supervisors and plans. When six trucks were found to be overweight on GVM, our operations team quickly came up with a solution.

Due to the concerted efforts of our drivers, workshop, loading and lashing and operations teams as well as the client’s clearance team, the cargo moved without delays and was safely delivered without any incidents or accidents.

Geotechnical Recce

This past month Alistair provided logistical and personnel services for a reconnaissance trip for the geotechnical study for the East African Crude Oil Pipeline.

The purpose of a geotechnical study is to study the suitability of the location of the pipeline route and the above ground installations and provide data necessary for the construction and engineering teams.

For this initial phase, we provided two (2) 4WD double cabin pickup trucks and utilised our professional network to enlist community liaison, security and medical experts for the job.

Kinyerezi Crazy!

This month has seen us step up our support for the two Power Plant projects in Dar es Salaam, Tanzania, providing a 60 ton crane for Kinyerezi 1 maintenance work and providing an extra 60 ton crane, a 4 ton Telehandler and 8 extra skilled riggers on top of our 250 ton crawler crane for the Kinyerezi 2 power plant.

After completing the final 99 ton heavy lifts on the project, our 250 ton crane has now had the boom fully extended to 60 meters in order to carry out the necessary finishing works at height. Our technical team now has the boom extension and reduction down to a six hour exercise and has maximized efficiency in order to keep operations running.

Alistair Group would like to thank our clients for making us their lifting and material handling company of choice.

Do you have any heavy lifting or power plant projects in the pipeline? Contact us today!

Transport to Namibia!

For any of you who have been following our newsletters for some time, you will know that Alistair Group enjoys the challenge of expanding to new geographies. Our recent establishment of a Zambian registered fleet of vehicles has allowed us to expand our reach to new corridors. This month we successfully completed our first trip moving consumables to Walvis Bay and backloading caustic soda to Lubumbashi. We expect to continue transporting cargo through Namibia using our Zambian registered fleet allowing for greater diversity of routes to better serve our customers throughout sub-saharan Africa.

Working Together, Working Better – Promoting Road Safety Awareness

We are proud to be able to support the North Star Alliance’s efforts to promote Road Safety Awareness. Alistair Group takes the welfare of its drivers seriously and actively promotes North Star Alliance’s commitment to bringing high quality health services to mobile populations, through building a network of public-private partnerships, and investing in sustainable practices. It was our pleasure to be able to share our defensive driver training program with over 160 truck drivers from a number of trucking companies who attended the Road Safety Awareness Day this month. We continue to actively promote and deliver defensive driver training to all of our subcontracted transporters and have further refined our own driver training delivery to ISO 9001:2015 standards.

Maintenance of an Access Road Near Afungi

Our Mozambique entity was recently recognized and commended on the excellent performance of our team during the maintenance of an access road in near Afungi. Our TLB was used for critical safety corrections along the main access road; this included selective tree removal along the roadway. Though the continuous interface with pedestrian, bicycle, motorbike, and vehicle traffic made the task especially challenging, our operator remained aware of the surrounding activities and completed the job without a single safety incident. Now there is a road that will function better and keep people far safer than in the past.

We would like to thank our client for continuously relying on us as their solution provider and allowing us to effectively support their project needs.

Load of The Month: 3,000 MT of Copper

Last month we uplifted 3,000 MT (102 trucks) of copper, blisters and cathodes over a period of 24 days. Our Road Freight Operations teams in Dar es Salaam and Solwezi planned out the flow, loading and dispatch of trucks to and from the mine in Solwezi.

The 2,170 Km trip averaged a 10 day transit time on both our own as well our subcontracted trucks, showing harmony in the standard operating procedures for this shipment. We appreciate the job well done by our team down at the mine, ultimately showcasing good loading efficiency and short turnaround time in Solwezi.

We look forward to another month of uplifting copper from Solwezi.

A Busy Month for our Dar es Salaam Warehouse

We continue to strengthen our warehousing division and this past month we had throughput of over 2,000 tons of copper via the warehouse! We welcomed two new clients to our warehouse in September and continue to field queries from many more clients.

We are currently in the process of developing our own in-house warehouse management system tailored to each client, this is what our clients have asked for and we believe will set us apart from the competition. Our technology team is working together with our

warehousing team to come up with a streamlined system of generating reports within minutes of offloading to keep our clients updated on their cargo in real time. At Alistair we are always striving to improve our processes; stay tuned for continued improvements to our warehousing system.

For any warehousing requirements, please contact us.

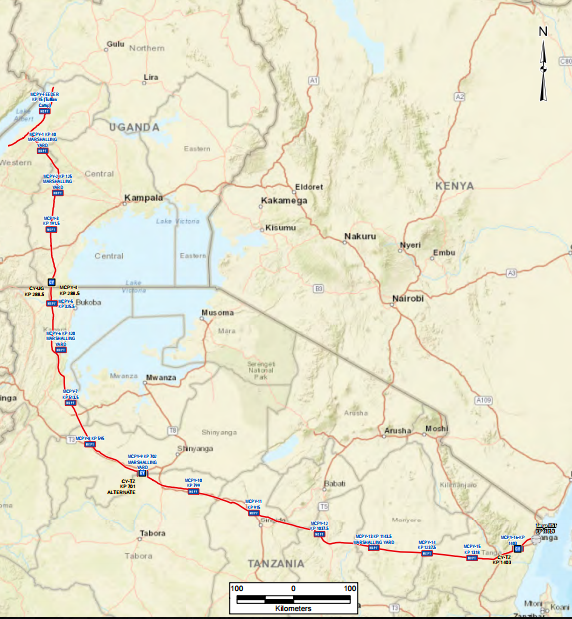

Load of the Month: East Africa Crude Oil Pipeline Route Survey

We recently had the opportunity to work with East Africa Crude Oil Pipeline (EACOP) staff members to conduct a route survey and feasibility study to transport 18m long and 12m long simulated pipes along the proposed supply route for the forthcoming East Africa Crude Oil Pipeline. The ultimate aim was to test the feasibility of transporting 18m pipes to three (3) key locations along the route.

Our Maintenance & Construction service line designed and built a dummy 18 meter load which was loaded and pre-positioned by the Road Freight service line team at ready for early departure from Dar es Salaam Port on 21 August 2017. Phase one of the trial was to transport the load along the transit route to the Uganda Main Camp Pipe Yard (MCPY 288.5) & proposed Uganda coating yard some 1,580Km away. All potential choke points along the route were proved to be passable and the transit time of 3 days easily achievable.

The team then dead-legged back to Dodoma (2-day drive) to start phase 2. This was the more challenging task of testing the pipeline access route from Dodoma to Tanga. Transit time was 1.5 days, which included 280Km of unpaved road – 74 Km of which was slow going and could prove challenging in the wet season.

After a total of 3,327 Km and 7 days’ travel, the convoy arrived in Tanga having proven that transportation of out-of- Gauge cargo to build what will be the longest heated pipeline in the world is indeed a reality.